Personnel, Particles & Processes: The Top Sources of Cleanroom Contamination

Time : January 09, 2026 View : 140

Cleanrooms exist to manage risks carefully. In fields like semiconductors, biopharmaceuticals, medical devices, and food processing, even small bits of contamination can halt production, harm products, or cause failures in compliance checks. Although sophisticated filtration and airflow setups draw plenty of focus, controlling contamination relies equally on people, supplies, and the cleanroom’s basic design.

Grasping the origins of contamination marks the initial move toward handling it properly. From routine staff actions to concealed particle emissions within wall sections, each element counts. This piece examines the three primary contamination origins—personnel, particles, and processes—and shows how thoughtfully crafted cleanroom sandwich panels from LAIRUN cut down these dangers through solid construction.

What Are the Main Personnel-Related Contamination Risks in a Cleanroom?

Workers play a vital role in cleanroom tasks, yet they remain one of the trickiest sources of contamination. Flakes from skin, bits of fiber, and particles stirred by motion can pile up fast if controls for personnel prove lax.

Prior to discussing building materials, it helps to see how everyday human actions impact cleanroom purity on a regular basis.

Personnel Hygiene and Behavior Controls

Human skin sheds particles steadily, even if staff seem tidy. Lacking firm hygiene habits, these bits float into the air and land on key surfaces. Cleanroom rules often cover hand washing, gowning steps, and managed entry areas. However, such measures function best when backed by walls and ceilings that avoid trapping dust or giving off their own particles.

Even surfaces that are sleek and non-absorbent cut down on particle sticking and boost the success of regular cleaning. Cleanroom sandwich panels featuring firm, sealed exteriors let cleaners and wipes perform as planned, rather than forcing dust into tiny crevices.

Staff-Induced Particle Generation

Motion stirs up particles. Steps taken while walking, twists of the body, and frequent door handling all disrupt air flows and raise particle numbers. This issue grows worse when wall sections bend, split, or shed fibers due to shakes. As time passes, minor flaws in structure can evolve into steady contamination points.

LAIRUN’s magnesium oxysulfide sandwich panels feature robust compressive power and fine size stability. Their solid inorganic center holds firm even in busy cleanrooms, thus lowering particle emissions from shakes or bumps.

Protective Apparel and Workflow Training

Garments for cleanrooms lessen direct shedding, but they fail to wipe out contamination entirely if workflows lack good planning. Repeated retracing of steps, packed areas, or fuzzy paths for materials heighten touches against walls and dividers. In those cases, the toughness of panels and their surface quality turn crucial.

Panels built with great strength endure extended use minus surface harm, so they fit nicely in cleanrooms that involve intricate staff paths or round-the-clock runs.

How Do Particles Originate From Materials and Processes?

Aside from people, numerous contamination threats arise from the supplies and gear employed within the cleanroom. Such particles prove tougher to spot since they accumulate gradually and stem from various spots. A cleanroom framework that curbs extra particle emissions holds a central part in managing this type of contamination.

Equipment Surface Shedding and Wear Debris

Devices produce particles via rubbing, shaking, and typical wear. With time, these bits shift into the atmosphere or rest on walls and roofs. Should wall sections take in dampness, warp, or fracture, they might hold debris and let it loose afterward amid cleaning or shifts in warmth.

LAIRUN’s thick paper honeycomb sandwich panels deliver a steady inner build with solid evenness and small risk of warping. Once sealed right, this panel type forms a reliable shield that stops dust from gathering inside wall spaces.

Process Residue and Chemical By-Products

Numerous cleanroom tasks use chemicals, solvents, or powders. Fumes and leftovers can coat wall exteriors and gradually weaken fragile materials. Sections that respond to dampness or chemicals might expand or crumble, sparking added contamination.

Magnesium oxysulfide panels, being inorganic and resistant to dampness, suit cleanrooms needing steady chemical handling and lasting toughness, particularly in labs and drug making.

Material Handling and Transfer Contaminants

Each spot for moving items—such as doors, pass boxes, or storage areas—opens a door for particles to slip into the cleanroom setting. Sections with snug connections and exact fitting lessen openings where dust might lurk. Systems with tongue-and-groove or precise matches aid in keeping unbroken surfaces, which speeds up cleaning and builds trust in results.

LAIRUN’s production background lets panel sizes and connection styles align with job needs, cutting back on-site trimming and curbing dust from building work.

What Structural Solutions Can Minimize Cleanroom Contamination?

While methods and tools count, the cleanroom’s physical makeup establishes the core level of purity. Bad choices in materials frequently create unseen contamination spots that cost a lot to repair down the line. Picking the proper sandwich panel stands as one of the sharpest ways to handle contamination over the long haul.

Magnesium Oxysulfide Sandwich Panel for Low Particle Release

Magnesium oxysulfide panels see wide use in top-tier cleanrooms thanks to their compact build and reliable action. LAIRUN’s magnesium oxysulfide sandwich panel employs a unique core mix that fights off damp uptake, splitting, and bending. As a result, the panel remains level and whole amid warmth shifts and routine tasks.

Such steadiness cuts particle emissions from core failures inside, so it works well for biopharmaceutical, semiconductor, and lab settings.

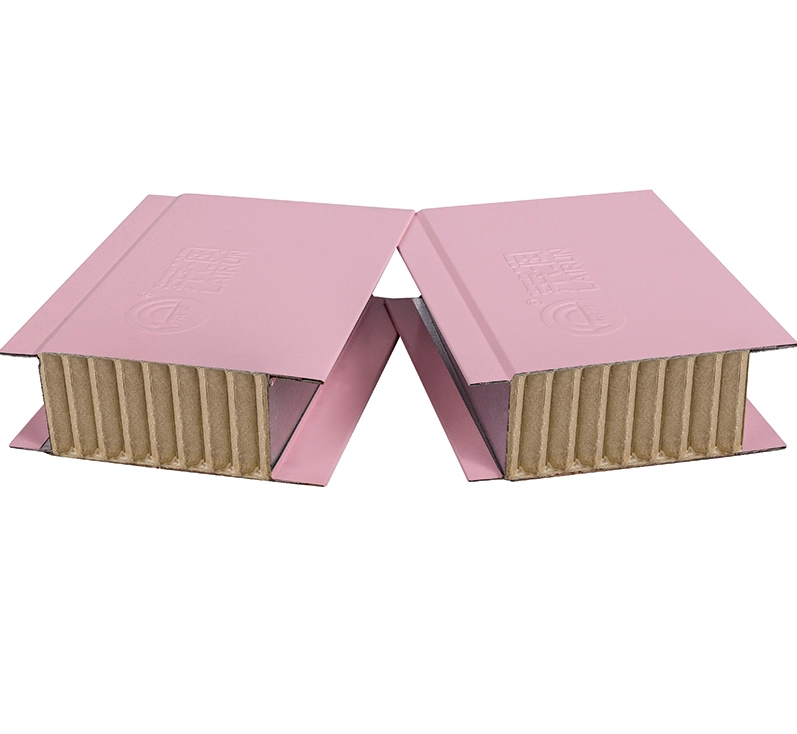

Thick Paper Honeycomb Sandwich Panel for Stable Particle Barrier

Paper honeycomb panels earn praise for their light weight and decent evenness in managed spaces. LAIRUN’s thick paper honeycomb sandwich panel gets built for cleanroom uses where cutting weight and sleek faces matter. If sealed well, the honeycomb center offers firm inner backing without dropping fibers.

These panels commonly serve spots with low dampness and steady warmth management, like cleanrooms for putting together electronics.

Rock Wool Sandwich Panel for Thermal and Dust Control

Safety against fire and warmth blocking also shape contamination handling. Swings in temperature might unsettle air flows, and materials rated for fire prove necessary in many controlled sectors.

LAIRUN’s rock wool sandwich panels blend Class A fire blocking with solid noise and warmth isolation. Their upright fiber setup aids in keeping panel firmness and lessens fiber shifts as years go by.

This setup makes rock wool panels a good choice for cleanrooms that demand fire guarding, sound handling, and ongoing firmness all together.

Why Is Panel Selection Critical for Cleanroom Environmental Control?

Cleanroom panels go beyond mere walls; they shape air flows, cleaning speed, and contamination chances throughout the facility’s full lifespan. Weak panel picks often spark steeper upkeep expenses and repeated purity problems.

Structural Integrity and Particle Suppression

Sections with soft centers or shaky materials can steadily emit particles through shakes, wear, or damp contact. LAIRUN stresses making panels with managed firmness, exact joining, and dependable side strengthening. This care for build aids in holding low particle counts well beyond setup.

Thermal Performance and Cleanroom Stability

Steady temperature aids reliable air flows and pressure handling. Sections lacking good blocking might lead to cool patches or moisture buildup, which raises contamination chances.

Panels of both magnesium oxysulfide and rock wool offer strong warmth handling, which bolsters cleanroom balance in varied work conditions.

Fire Safety and Long-Term Contamination Prevention

Materials rated for fire are standard in most cleanroom builds, but fire traits must not harm purity. Inorganic centers like magnesium oxysulfide and rock wool keep fire blocking without giving off bad fumes or fibers in everyday use, thus aiding safer and purer runs over time.

How Can LAIRUN Products Integrate With Cleanroom Best Practices?

Cleanroom results hinge on how materials, setups, and oversight methods mesh. Structural sections ought to aid, not hinder, daily work. LAIRUN shapes its goods with this blending in view.

Combining Panels With Standard Cleanroom Protocols

Sleek faces, tight links, and firm centers ease everyday cleaning and sharpen its impact. Sections that stand up to chemical cleaners and ongoing wipes aid in upholding hygiene marks without face harm.

Optimizing Cleanroom Layout With LAIRUN Sandwich Panels

Tailored sizes and adaptable setup choices trim on-site slicing, a usual cause of build dust. LAIRUN’s machine-driven lines yield steady panel quality, so jobs hit strict timelines without losing purity.

Maintenance Strategies to Sustain Low Contamination

Tough panels lessen needs for fixes, swaps, or patches, each of which brings contamination risk. With sound material picks from the outset, cleanrooms hold their edge with fewer stops and slimmer costs over years.

FAQ

Q1: Which sandwich panel is best for high-grade pharmaceutical cleanrooms?

A: Magnesium oxysulfide sandwich panels are often preferred due to their dense, inorganic core, moisture resistance, and low particle release characteristics.

Q2: Are paper honeycomb panels suitable for all cleanroom environments?

A: Paper honeycomb panels work well in dry, temperature-stable cleanrooms such as electronics assembly areas, but may not be suitable for high-humidity environments.

Q3: How do cleanroom panels affect long-term contamination control?

A: Stable, non-deforming panels prevent hidden particle release over time, making daily cleaning more effective and reducing the risk of contamination buildup.