Top 10 Cleanroom Technology Brands Dominating the 2025 Global Market

Time : January 15, 2026 View : 28

Selecting the proper cleanroom supplier can be a crucial challenge. For instance, whether you are constructing a semiconductor facility or a biotechnology laboratory, the barriers you select serve as the initial barrier against pollution. As we approach 2025, the industry is quite competitive, yet LAIRUN emerges as a prominent option that has secured its position among the leading 10 cleanroom panel brands in China. With more than 25 years of research and development knowledge, they deliver the practical strength needed for the planet’s most delicate testing and manufacturing settings.

Which Companies Lead the Global Cleanroom Panel Industry in 2025?

The field of cleanroom production has evolved toward large-scale, technology-driven plants that manage substantial international requests without sacrificing standards.

Top 10 Global Brands and Lairun Group’s Market Leadership

When examining the top 10 international brands, Lairun Group appears frequently, particularly in Southeast Asian and Australian regions. They have operated officially under the LAIRUN brand since 2012, although the experts involved possess over 25 years of thorough research and development background. It is this combination of traditional skills and contemporary labeling that has positioned them as a premier Chinese brand.

Strategic Advantage of Advanced Automated Production Systems

Capacity is vital when facing tight project timelines. Lairun runs a 38,000-square-meter site in Foshan. Equipped with eight automated production lines that generate 25,000 square meters daily, they possess the capability to fulfill large-scale requirements that lesser operations simply cannot achieve. Their yearly output value has reached 400 million RMB, demonstrating their status as a major player in this sector.

Specialized Protection for High-Tech and Medical Industries

It goes beyond simply creating “walls”; rather, it involves offering safeguards customized to particular hazards. Lairun’s equipment supports applications from renewable energy and semiconductors to food processing and healthcare facilities. They have delivered products to more than 30 nations, establishing a track record for dependable post-sale assistance and affordable rates that suit worldwide initiatives.

Although understanding the firm’s history is useful, the true benefit comes from the actual panels. Now, let us explore the particular substances that currently establish the benchmark for effectiveness.

What Are the Most Reliable High-Performance Cleanroom Panels?

Picking the appropriate core substance is likely the key choice in your cleanroom construction. Depending on needs like fire resistance or dampness tolerance, your selection will differ.

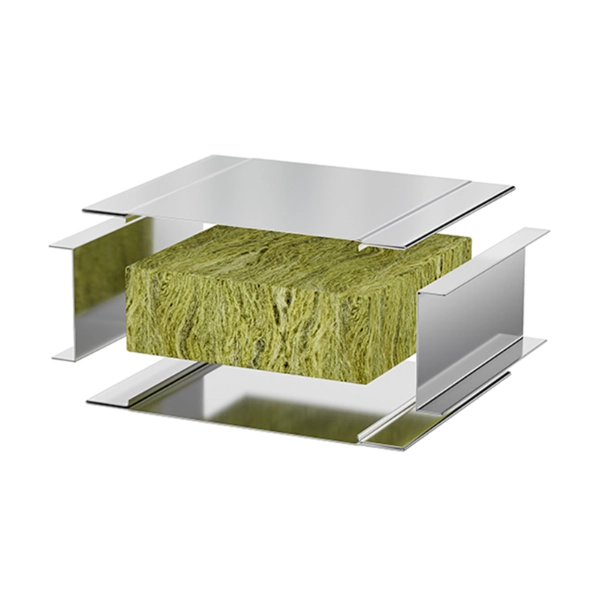

Rock Wool Sandwich Panels for Superior Fire Safety

If fire protection ranks as your primary concern, Lairun’s Rock wool sandwich panel stands out as the preferred option. These panels incorporate dense rock wool fibers—derived from natural rocks such as basalt—positioned at right angles to the metal surface for added robustness. They achieve Class A fireproof rating, so they resist ignition, and moreover, they deliver strong noise reduction for loud industrial areas.

Silica Rock Sandwich Panels for Enhanced Thermal Insulation

For situations requiring a mix of durability and heat management, Lairun’s Silica rock sandwich panel proves to be a reliable choice. It excels at limiting heat movement, which is essential for laboratories or chemical storage where small temperature shifts might spoil production. Additionally, it endures the demands of a active site well.

Thick Paper Honeycomb Sandwich Panels for Lightweight Durability

At times, a lighter alternative is necessary, particularly for overhead frameworks. Lairun’s Thick paper honeycomb sandwich panel provides solid stiffness without the substantial mass of mineral-based fillings. Thus, it becomes an effective selection for dividers where a neat appearance and simple manipulation during setup are desired.

Even superior materials might underperform without robust quality oversight. This is where Lairun’s internal “SVB” approach plays a critical role.

Why Is the SVB System Essential for Quality Assurance?

Quality management in the sandwich panel sector is frequently opaque, but Lairun aims for clarity via their SVB (Scientific, Verbund, Butler) framework.

Scientific Research Parameters and Formula Innovation

The “Scientific” element focuses on laboratory efforts. Lairun does not merely purchase supplies; instead, they create their own recipes. Their patented Magnesium Oxysulfide (MOS) core serves as a prime illustration—it is designed to resist dampness and fungal growth without the typical “halogen return” problems found in lower-cost panels.

Verbund Integrated Production for Supply Chain Stability

“Verbund” describes their unified method. They maintain affiliated firms, such as Lideng Building Materials, which manufacture the essential core elements. By producing their own glass magnesium and magnesium sulfate boards, they maintain strict control over standards and costs, thereby extending those advantages and dependability to clients.

Butler Style Service for Comprehensive Customer Support

The “Butler” service indicates they do more than dispatch shipments and vanish. They provide round-the-clock technical guidance and a complete support network that spans from preliminary needs evaluation to ongoing after-sales care. Furthermore, they supply complimentary samples, allowing you to assess the quality firsthand prior to a large purchase.

Past the substances and support, the manufacturing process for these panels can significantly lower expenses during building phases.

How Does Intelligent Manufacturing Reduce Construction Costs?

In construction, time directly translates to expense. If panels prove difficult to assemble or arrive with inaccurate sizes, your workforce expenses will surge.

Automated Manual Production Lines for High Precision

Lairun has allocated over 100 million yuan toward automated manual production lines. Though this may seem contradictory, it represents an advanced technique that combines machine accuracy with the structural merits of crafted panels. Consequently, this system manages tasks from panel shaping to thermal pressing in a single sequence, resulting in reduced mistakes and quicker delivery.

Tongue and Groove Designs for Rapid Installation

If you have dealt with intricate connections before, you will value the tongue-and-groove configuration. These panels fit together smoothly and can be secured using self-tapping nails. Because of this distinctive feature, setup can proceed at double the pace of conventional approaches, which in turn may halve your labor expenditures.

Customization Options for Reduced On-Site Waste

One major issue at work sites is trimming panels to match. Lairun provides tailoring for dimensions like length, width, and depth (50mm, 75mm, 100mm). They can also integrate electrical conduits or create openings in advance at the plant, so upon arrival, the panels are prepared for immediate use.

With expenses managed, the concluding phase involves ensuring the panel aligns with your sector’s unique conditions.

Where Can These Specialized Cleanroom Solutions Be Applied?

Each sector faces its distinct “troublesome” contaminants. For some, it involves flames; for others, microbes or electrical charges.

Medical and Biopharmaceutical Contamination Control

In medical centers and pharmaceutical workshops, purity is not merely an aim; it is a regulation. Lairun’s panels for medical use are antimicrobial and straightforward to sanitize. They frequently employ aluminum supports to enhance sturdiness, guaranteeing that the barriers withstand the load of healthcare devices while remaining germ-free.

Semiconductor and Electronics Manufacturing Stability

For semiconductor initiatives, such as the project Lairun completed in Dongguan, every minor aspect is significant. They utilize targeted rock wool and glass-magnesium rock wool panels to maintain environmental consistency. The 0.476 mm color-coated steel plates offer the resilience and rust resistance required for these precise advanced technology areas.

Food and Daily Chemical Product Safety Standards

Food plants must cope with elevated moisture levels and mold threats. MGO (Magnesium Oxide) rock wool panels suit these conditions ideally since they repel water and promote hygiene. The secure “Tongue and Groove” connections prove invaluable because they block dust accumulation in gaps, thereby helping the site comply with protection guidelines.

FAQ

Q1: Is it better to get handmade or machine-made panels?

A: This depends on your funds and specifications. Machine-made panels are quicker and more economical. On the other hand, handmade panels provide superior edge alignment, enhanced sealing, and greater weight support, which is why they typically serve as the preferred option for high-end cleanrooms.

Q2: Can these panels really save me 50% on labor?

A: Indeed, this is mainly due to the tongue-and-groove linking mechanism. Since the panels connect effortlessly and demand minimal cutting on location, the assembly rate is roughly double that of standard techniques.

Q3: What happens if the environment is very humid?

A: In areas with high moisture, certain substances like ordinary glass magnesium should be avoided if levels drop below 30%. Rather, consider Lairun’s Magnesium Oxysulfide or dedicated rock wool variants that are engineered for water resistance and mold prevention.