Best Practices for Designing and Maintaining Clean Rooms in Hospitals

Time : January 16, 2026 View : 11

In the intense arena of medical care, the framework of a structure performs roles well beyond simply bearing the weight above. Hospital clean rooms function as dedicated zones where each section is engineered to resist microbes, ward off flames, and preserve cleanliness amid demanding circumstances. LAIRUN, supported by 25 years of practical sector knowledge and an extensive 38,000-square-meter operation in Foshan, stands as the reliable collaborator for medical centers requiring sturdy, healthcare-standard partitions and overhead systems.

Constructing such areas involves more than adhering to a design; it centers on picking substances that simplify operations for physicians within and for the staff handling ongoing care of the site.

Why Is Rapid Installation Critical for Hospital Construction?

Whenever a medical facility calls for a fresh operating area or a drug preparation space, each postponed day translates to untreated individuals. Pace is essential, yet standards must remain intact because health outcomes hinge on them.

Superior Efficiency With Tongue-and-Groove Joints

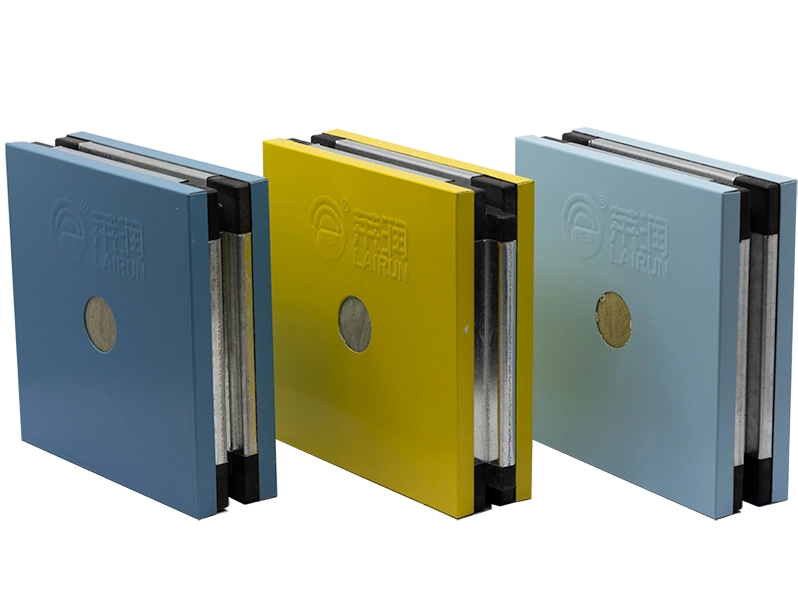

The Male-Female Jointing Rabbet Laminboard represents a significant improvement for pressing timelines. Rather than struggling with complex fixings, these sections employ an intelligent interlocking pattern that connects smoothly. Workers align them securely and attach using self-tapping screws, and this arrangement generally lowers workforce expenses by around 50% since the group advances at roughly double the rate possible with conventional substances.

Versatile Core Materials for Safety

Protection in a medical setting does not follow a uniform approach. Based on the space’s purpose, the inner fillings of these sections can be exchanged. In zones subject to elevated temperatures, Rock Wool serves as a dependable selection because it attains Class A non-combustible status and avoids ignition. When the area demands aridity and reduced weight, Magnesium Oxysulfide (MOS) proves more suitable as it resists deformation or water retention.

Durable Surfaces for Sterile Environments

The outer layers of these sections hold equal significance to their interiors. Through the application of 0.476 mm painted steel or corrosion-resistant steel, LAIRUN guarantees that the barriers withstand repeated washing with potent sanitizers. These exteriors are compact and microbe-repelling, ensuring that fungi and pathogens lack suitable habitats, which aligns perfectly with needs for healthcare divisions.

Transitioning from barriers to the concealed elements beyond them, planners in hospitals must also address the vital conduits of the space—such as power and gas pathways that sustain clinical devices.

How to Manage Complex Electrical Wiring Safely?

Few elements compromise a clean space’s purity more swiftly than visible cables or prominent outer channels that accumulate particles. Concealing all components is crucial for maintaining pure atmosphere and a refined aesthetic.

Seamless Integration With Embedded Pipes

The Embed Line Pipes Rabbet Laminboard is crafted to conceal such disorder. It incorporates channels pre-embedded in the filling, permitting cables to route directly via the barrier’s core. Consequently, the entire setup appears orderly, and more vitally, it safeguards the area from particle collection points that typically arise near exposed fittings.

Flexible Material Options for Conduits

Since no initiative is identical, these sections provide adaptable configurations. Choices encompass zinc-coated tubing or plastic tubing for the embedded routes, selected according to municipal guidelines or the demands of particular clinical apparatus. This minor choice averts considerable difficulties amid the construction phase.

Enhanced Load-Bearing and Fire Protection

Despite integrating channels within, these sections preserve their robustness. By utilizing compact Rock Wool, they achieve the Class A flame resistance level and offer effective acoustic damping. As a result, the interior remains sufficiently serene for patient recovery, regardless of substantial external sounds.

With barriers and cabling resolved, emphasis moves to the upper region. The overhead structure hosts the most sophisticated ventilation processes, necessitating particular fittings to operate effectively.

What Is the Best Solution for Cleanroom Ceilings?

In a hospital clean space, the overhead is far from a mere enclosure; it forms an integral aspect of the ventilation network. Should it permit airflow escapes, the entire zone would not pass hygiene evaluations.

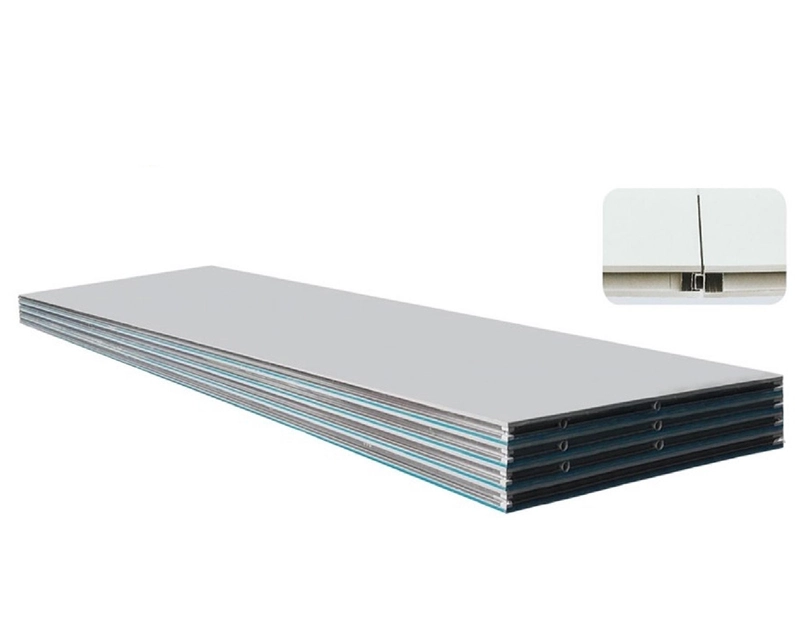

Airflow Control With Specialized Blind Plates

The FFU Ultra-Thin Metal Ceiling Clapboard (frequently termed a manual blind plate) is the tool that specialists apply to regulate circulation. These components fit hospital overheads ideally since they seal airflow through openings and halt particles or microbes from descending from the cavity above.

High Strength and Precision Manufacturing

As these components emerge from mechanized processes, their measurements remain precise consistently. LAIRUN integrates substances like Aluminum Honeycomb or Gypsum into the filling to confirm the components are manageable in weight for placement yet resilient enough to prevent drooping or distortion across years.

Customizable Coatings for Chemical Resistance

Overheads in medical facilities encounter numerous cleansing substances. These components can receive static-dissipating finishes or even 304/316 stainless steel for more severe conditions. Thus, degradation or surface breakdown does not occur after half a decade, thereby stabilizing upkeep expenditures.

Erecting a space that appears immaculate at inception is achievable, but sustaining that purity through prolonged, nonstop activity presents a greater challenge. Here, the fundamental properties of the substances play a pivotal role.

How Does Material Quality Impact Long-Term Sterility?

Selecting low-cost substances may reduce preliminary outlays, but within a medical context, this frequently results in fungal proliferation, erosion, or sections that disintegrate owing to ambient dampness.

Advanced Magnesium Oxysulfide Technology

LAIRUN has dedicated substantial effort to their protected Magnesium Oxysulfide (MOS) composition. Distinct from prior “magnesium chloride” sections that retained liquid and corroded metal exteriors, this contemporary MOS filling is entirely impervious to humidity. It avoids condensation or emission of halogens, establishing it as the prime option for research areas and medical sites demanding unwavering settings.

Rigorous Testing and Quality Assurance

Quality transcends mere phrasing in this context; it constitutes a framework. LAIRUN employs their termed SVB system—Scientific, Verbund, and Better Service. Each individual section receives scrutiny against firm benchmarks prior to departure from the Foshan worksite, verifying alignment with ISO 9001 and ISO 14001 approvals.

Impact Resistance and Structural Longevity

Medical sites operate with constant motion, where wheeled units and devices routinely contact barriers. Hence, numerous opt for LAIRUN’s manually assembled sections, incorporating galvanized keel edging. This additional internal structure renders the barrier far more resilient and capable of enduring collisions without indentation or compromise to its enclosure.

Identifying suitable items comprises partial effort, but engaging an appropriate provider for those items is what propels the undertaking to timely and budgetary completion.

Why Is LAIRUN the Preferred Partner for Global Projects?

Amid abundant vendors, why do endeavors from the US to Australia persistently return to an establishment in Guangdong? It generally boils down to their ability to tackle substantial tasks while retaining individualized engagement.

Large-Scale Automated Production Capacity

LAIRUN operates beyond a modest scale. Their premises encompass 38,000 square meters and operate 8 fully automated production lines. They generate 25,000 square meters of sections each day, meaning that for medical undertakings requiring large volumes promptly, they hold the resources to fulfill.

Decades of Research and Innovation

The personnel do not simply pursue patterns; they establish them. Possessing over 25 years of experience and 9 patents, the directors at LAIRUN comprehend the engineering facets of clean spaces more thoroughly than many. They have observed the sector’s development—from initial phases of basic layered sections to present sophisticated, healthcare-oriented resolutions.

Proven Reliability Across 30 Countries

Be it a chip fabrication site in Dongguan or a clinical installation in Europe, LAIRUN has participated. They have distributed to over 30 countries, cultivating a firm standing for equitable rates and—perhaps chiefly—consistent post-delivery assistance. Associating with them yields an elite-grade item supported by years of regional fabrication commitment.

FAQ

Q1: Which is better for a hospital: Rock Wool or Magnesium Oxysulfide?

A: The selection varies with the space’s role. Rock Wool prevails for flame guarding and noise reduction, rendering it suitable for boisterous regions or sites with rigid flame regulations. Magnesium Oxysulfide (MOS) excels in research or moist zones because it completely blocks dampness and prevents fungal development.

Q2: How do handmade panels differ from machine-made ones?

A: Manually produced sections often incur higher fees yet deliver enhanced exactness and durability due to the embedded galvanized keel. Additionally, they facilitate broader tailoring, such as advance perforations for glazing or incorporated channels for cabling.

Q3: Can these panels be used for both walls and ceilings?

A: Indeed. The bulk of Tongue-and-Groove and Handmade sections are formulated to serve as interior separating barriers and overhead sections in decontamination facilities. For particular overhead needs, the FFU Blind Plates are frequently included to mesh with ventilation apparatuses.